Featured Services

Spanish Interpretation for Selected Trainings

New! Spanish translation available for select courses. ¡Nuevo! Traducción al español disponible para cursos selectos. ¡Haga clic abajo para leer más!

Energy Diagnostics and Analysis

The BPC’s technical staff combines experience gained from working on over 1,000 buildings with science-based, expert knowledge of building performance.

Environmental Investigations

The BPC can identify and test for many different indoor air quality issues and potentially dangerous materials and create a strategy for a healthier indoor environment.

reducing emissions

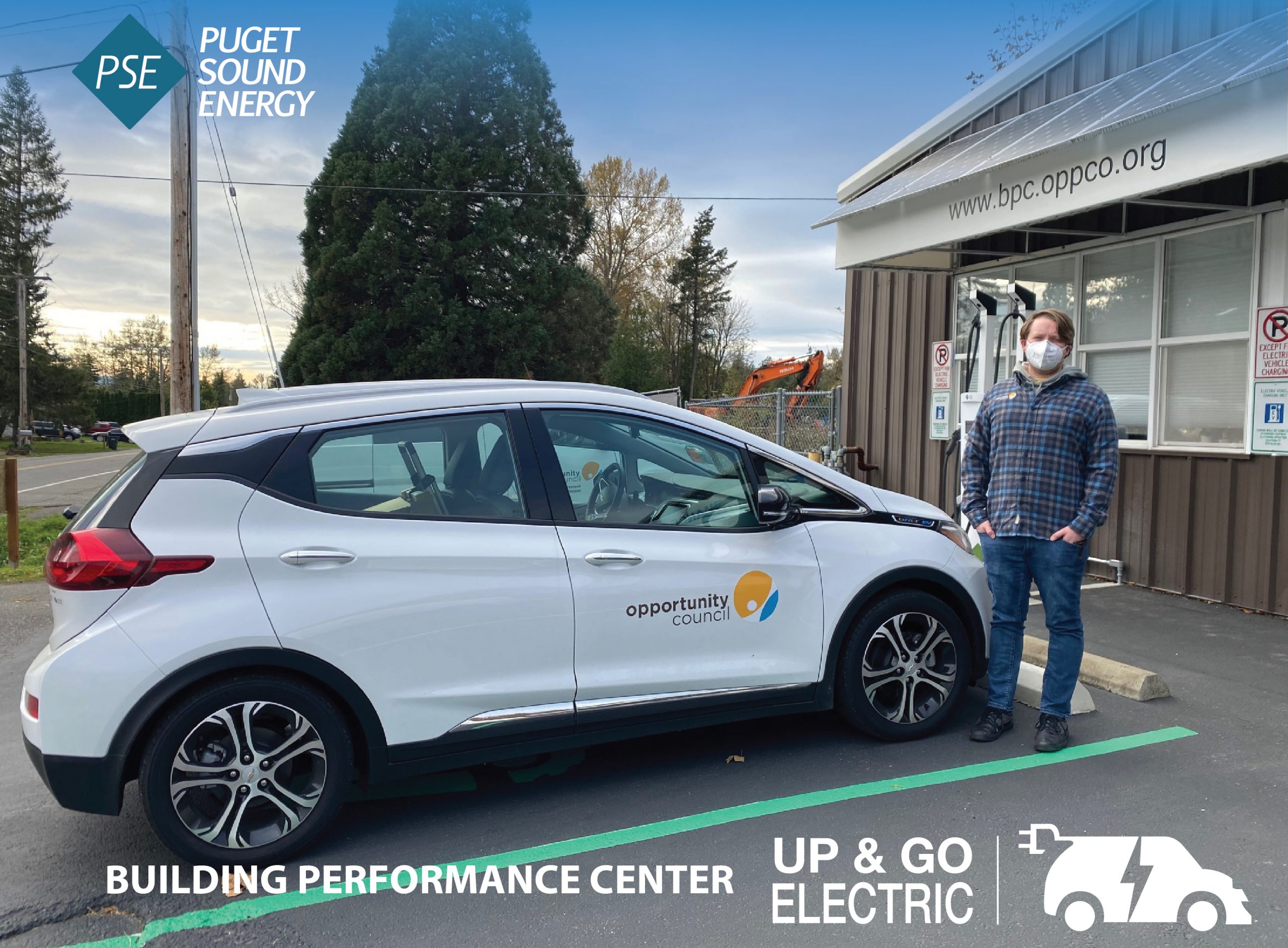

BPC partners with PSE!

This electric vehicle is expanding services to low-income households through a lower cost fuel source with zero emissions. Our Conservation Education team has already saved energy while delivering energy saving items to clients in our low income Weatherization program. PSE is committed to carbon reduction and supporting the growth of electric transportation in our region.

Hands-on, in person, and online options

Our approach and focus on quality result from over 30 years of experience, so you can be sure you’ll gain the skills, knowledge or results you seek from any of our courses.

Upcoming events

Courses

Interested in becoming a weatherization professional? Need to update your current weatherization skills or earn certification?

Through the BPC’s proven training programs, you’ll learn new skills in hands-on labs. Our trainers are weatherization experts with decades of experience.